Then joint plane and sand to final shape. If you do encounter stress save the wood for small parts.

36 Woodworking Joints Easy To Make 2019 Update

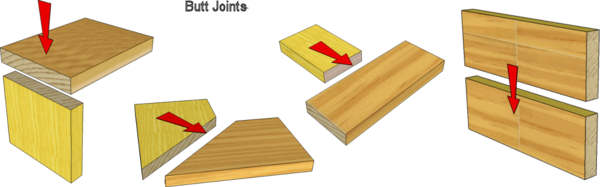

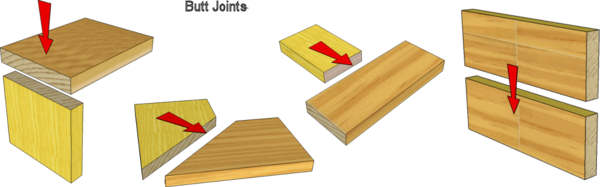

Fame joint Case joint Panel joint Edge joint Blind joint Through joint Reinforced joint.

What is a stressed joint in woodworking. For Titebond Polyurethane Glue we recommend clamping for at least forty-five minutes. If a joint is under stress maintain clamping pressure for the full cure time Cure time. A good joint will split mostly in the wood adjacent to the glueline.

Joints with slopes of 1 in 10 or 1 in 12 were found to attain tensile strengths equal to 85 to 90 percent of the strength of clear wood. For this reason the strongest joint for wood will occur if the glue is applied within minutes after the surface is properly prepared and of course the correct pressure follows promptly. A joint technique most commonly used in woodworking joinery.

In summary the weight wood glue can hold is the stress on a glue joint before it breaks. PVAs and hide glue offer only 30-50 of full strength at stated time. Its affected by humidity and temperature the level of surface prep and whether youve applied too little or too much clamping force.

Keep in mind that higher temperature drier wood and lower humidity speed drying time. The glue is completely cured within 6 hours. A cut is made through the neck blank at the desired headstock angle and the off cut forms the headstock.

A scarf joint is an angled joint between the neck and the headstock. What is a scarf joint. We recommend not stressing the new joint for at least 24 hours.

It will start to move with less force and none of the joint might have gone past the limit of its elasticity yet. Considerable work has been done on this type of end joint. The glue is completely cured within 6 hours.

The additional wood thickness between the headstock and the heel is also mostly cut away creating waste. When the glue joint is stressed the wood can snap before the wood glue bond breaks. A weak joint will split in the glueline either because the glue was too thick or the glue didnt penetrate the wood correctly.

For Titebond Polyurethane Glue we recommend clamping for at least forty-five minutes. We learnt that some glues will not be able to reach their stated strength if theres any more than 2 difference in the moisture content between the pieces of wood. The percentage of wood failure will be very low or nonexistent.

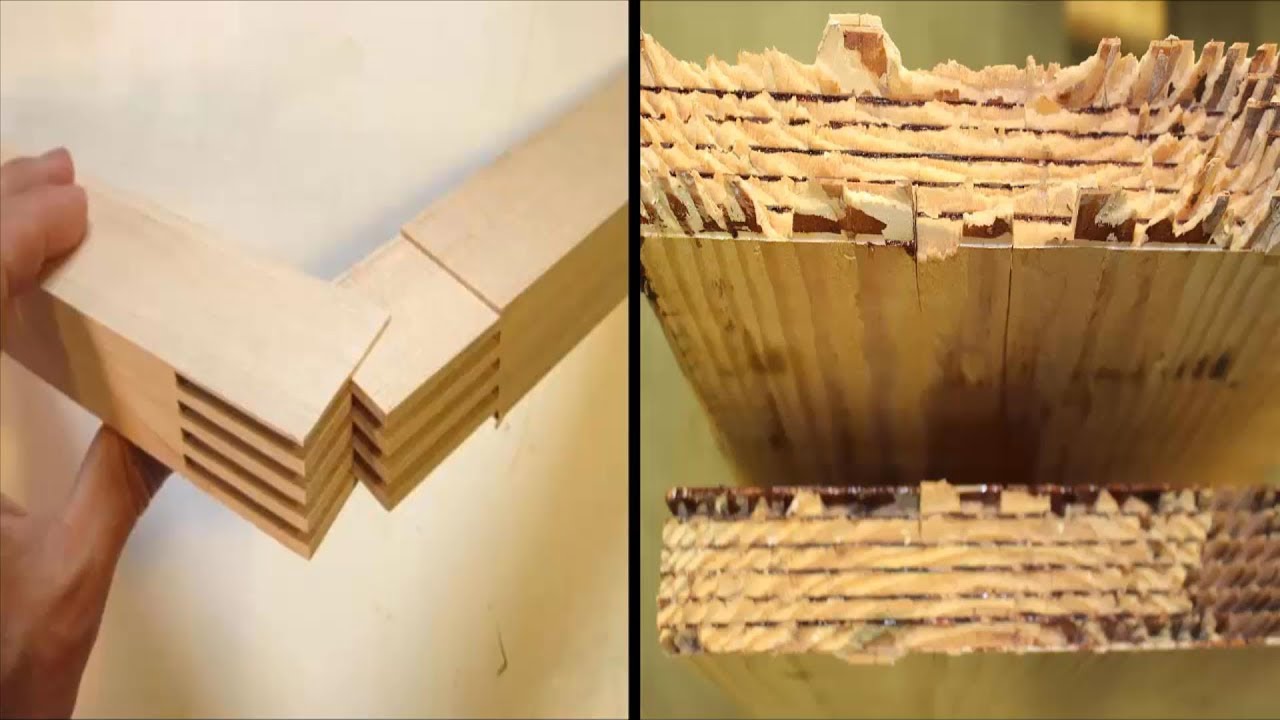

This depends on the type of wood as well as the glue strength. For most of our wood glues we recommend clamping an unstressed joint for thirty minutes to an hour. Noted for its resistance to being pulled apart tensile strength the dovetail joint is commonly used to join the sides of a drawer to the front.

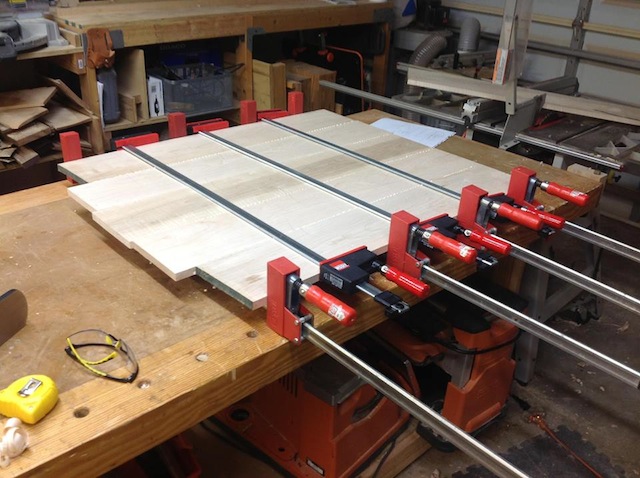

At a slope of 1 in 20 the average was approximate-ly 95 percent of the strength. Stressed joints need to be clamped for 24 hours. The desk is about 175 feet long in total and about 20 inches deep although it does vary quite a lot.

Most lumber from high-volume hardwood dealers comes from managed forests containing few growth-stressed trees. The work was all done on site with the major tools being a router circular saw jig saw and belt sander. Through wood thickness-thus expos-ing wood that approaches side gram.

As a matter of fact the wood can be the weakest link in the glue joint. So how strong is the wood youre using. It is composed of 3 slabs in total both joints are curved but each is different.

Stressed joints would be things like a bent lamination. Kenji Horvath Stressing the Joint is as simple as lifting the glued up wood level which puts gravity stress on the joint. If your wood is on the bench in clamps and you flip the wood over so when the clamps are removed the wood with your assistance so it does not drop onto the table putting further stress onto the joint.

The period of time that glue remains useable. The time it takes for a glue joint to achieve full 100 bonding strength. The less wood in the part the less pent-up stress and warpage potential.

While lower temperature wetter wood and higher humidity slow it. A joint is going to be judged as insufficient when the wood starts to move not when it breaks.

Better Glue Joints Popular Woodworking Magazine

Joinery Basics Types Of Basic Joint Stress Youtube

Butt Joint Connection For Timber Two End Pieces Of Wood Butted Together

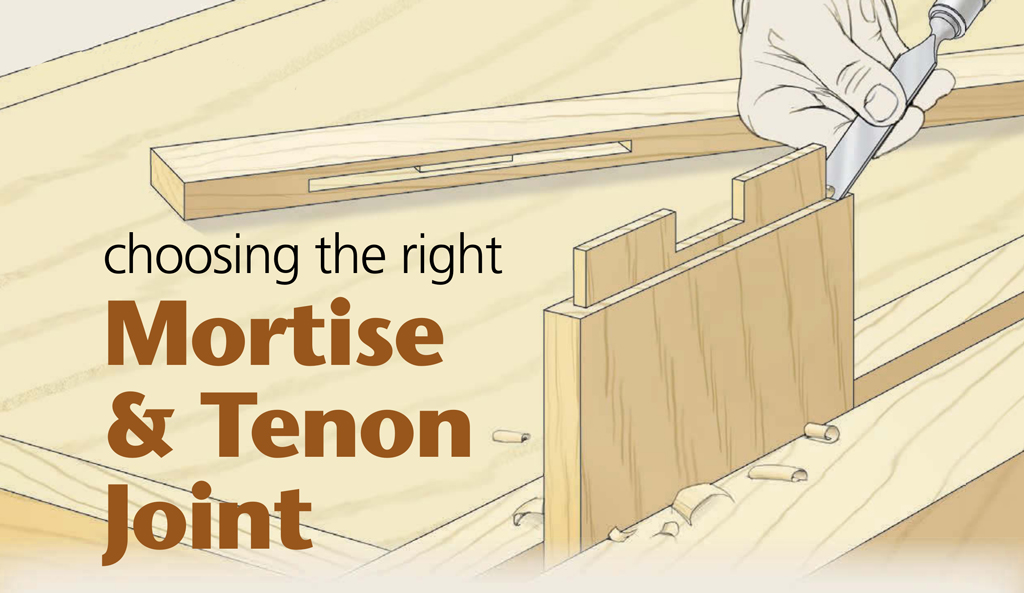

Choosing The Right Mortise Tenon Joint Woodsmith

Lap Joints With Hand Tools Start Woodworking Class Seven Youtube

Butt Joint Connection For Timber Two End Pieces Of Wood Butted Together

Which Is Better For A Joint Wood Glue Or Screws Quora

How Long Do You Leave The Clamps On A Glue Up Project

Interior Glue Joint Torture Test Wood Magazine Youtube

Better Glue Joints Popular Woodworking Magazine

Successful Wood Joints Wood Moisture Content

How Long Before Removing Clamps The Wood Whisperer

4 Types Of Wood Joints And When To Use Them Craftsy

Best Wood Glue Surface Smooth Or Rough Popular Woodworking Magazine

Joinery So Amazing I Had To Share Wood Joints Woodworking Joints Wood Joinery

The Best Wood Glue Glue Blogs Action Adhesives